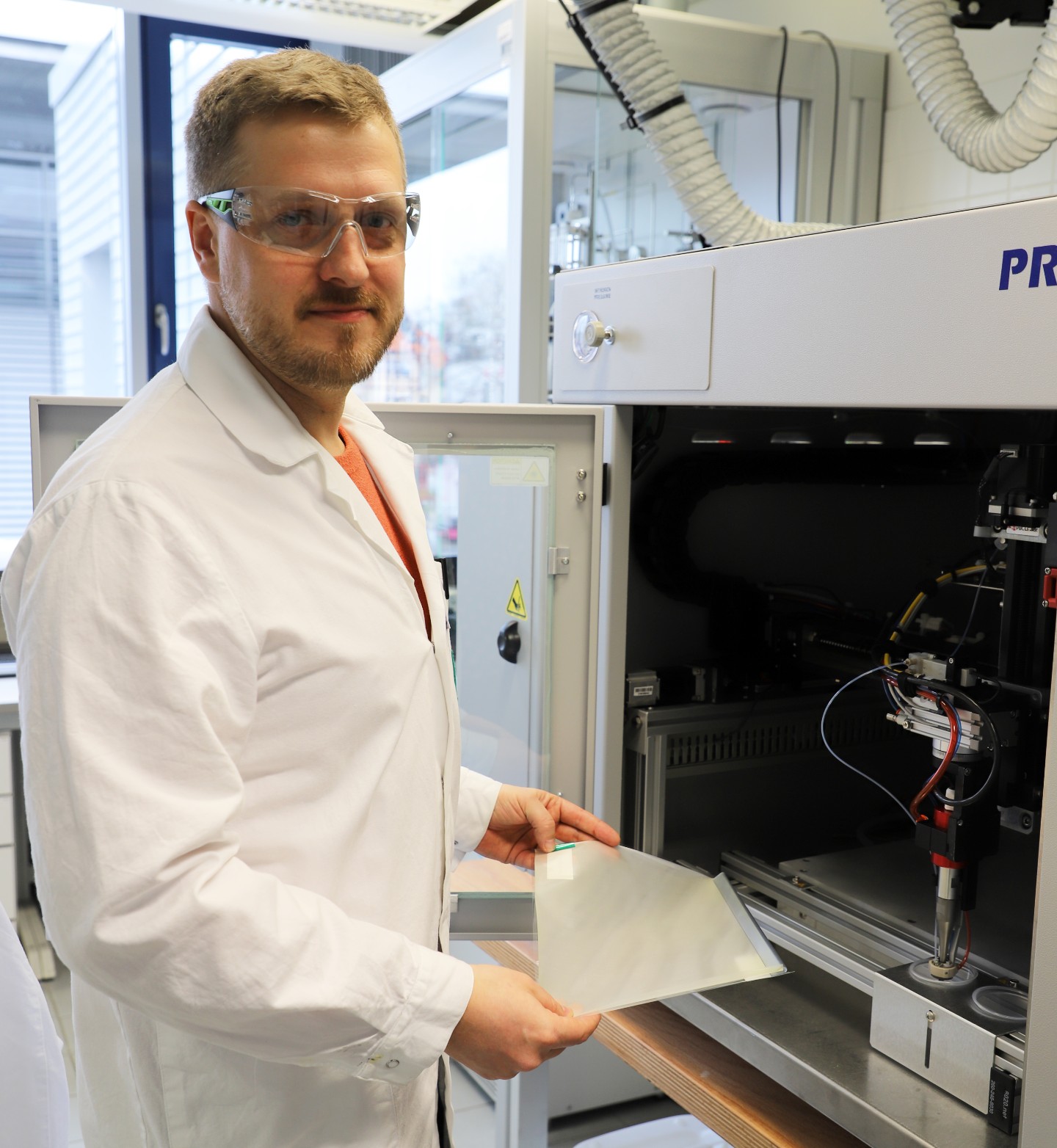

On April 1st, the EU-funded initiative FlexFunction2Sustain was launched.

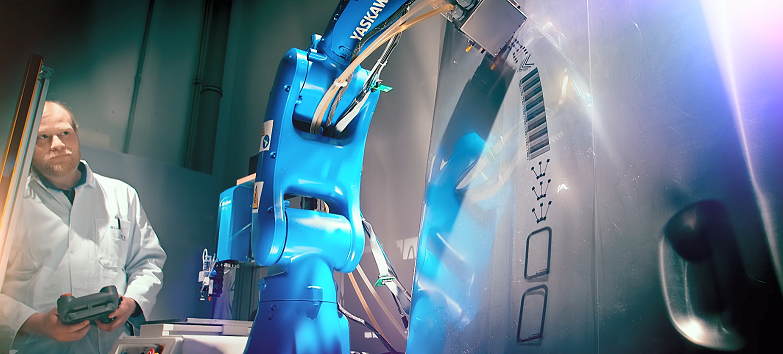

The project, financed by the European Union’s Horizon 2020 research and innovation programme, will support Plastics and Paper Processing Industry in overcoming environmental challenges while entering the digital age. 19 European partners, including Fraunhofer Institutes FEP, IAP and IVV, unify their competencies, practical and business development expertise and technical infrastructure to provide a wide access to innovative solutions through a sustainable open innovation ecosystem. This Open Innovation Test Bed for nano-functionalized plastic and paper surfaces and membranes will support innovative SMEs and industries by drastically reducing the time-to-market for novel concepts, ideas and products.

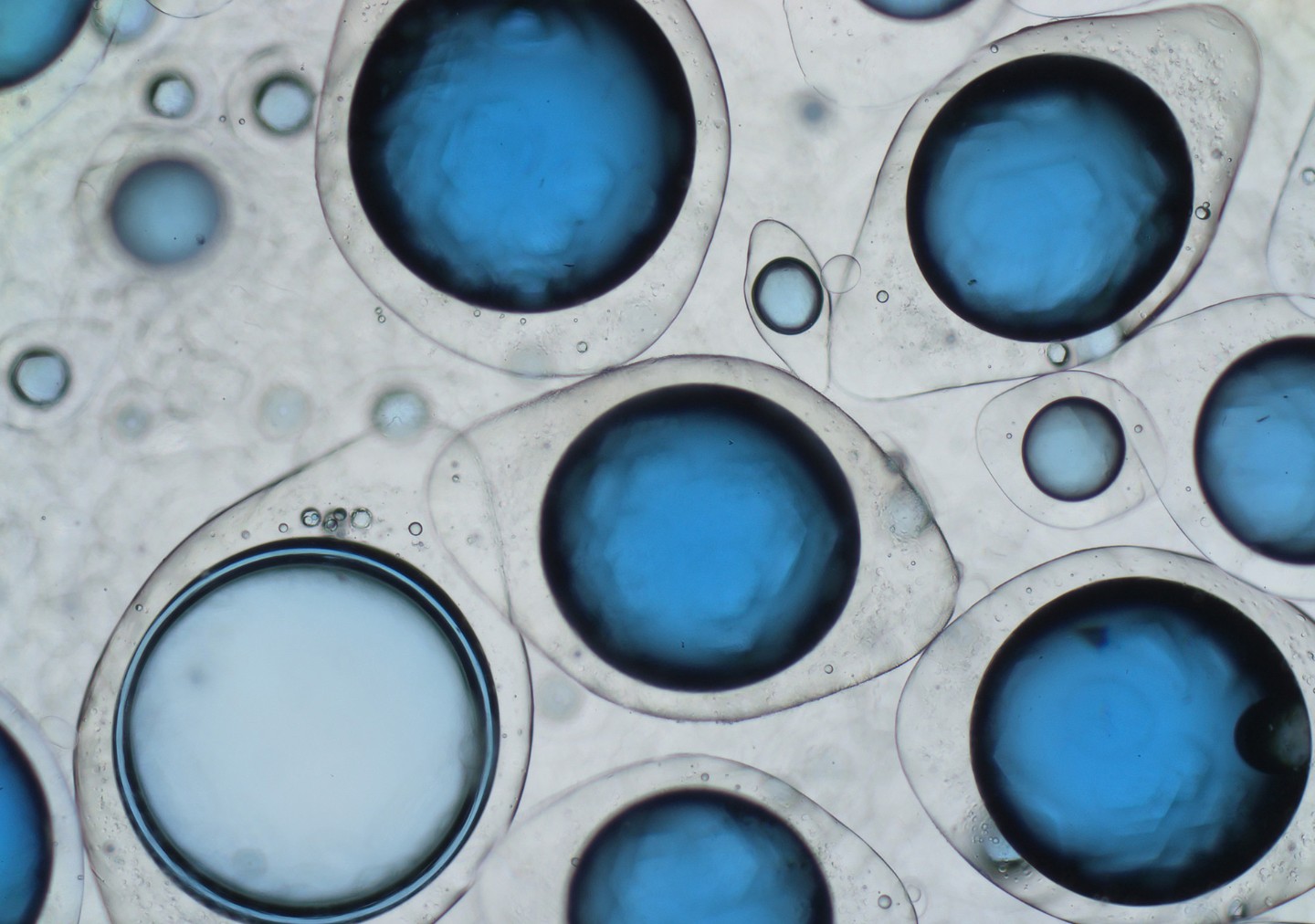

Nano-functionalisation for smart and sustainable plastic surfaces

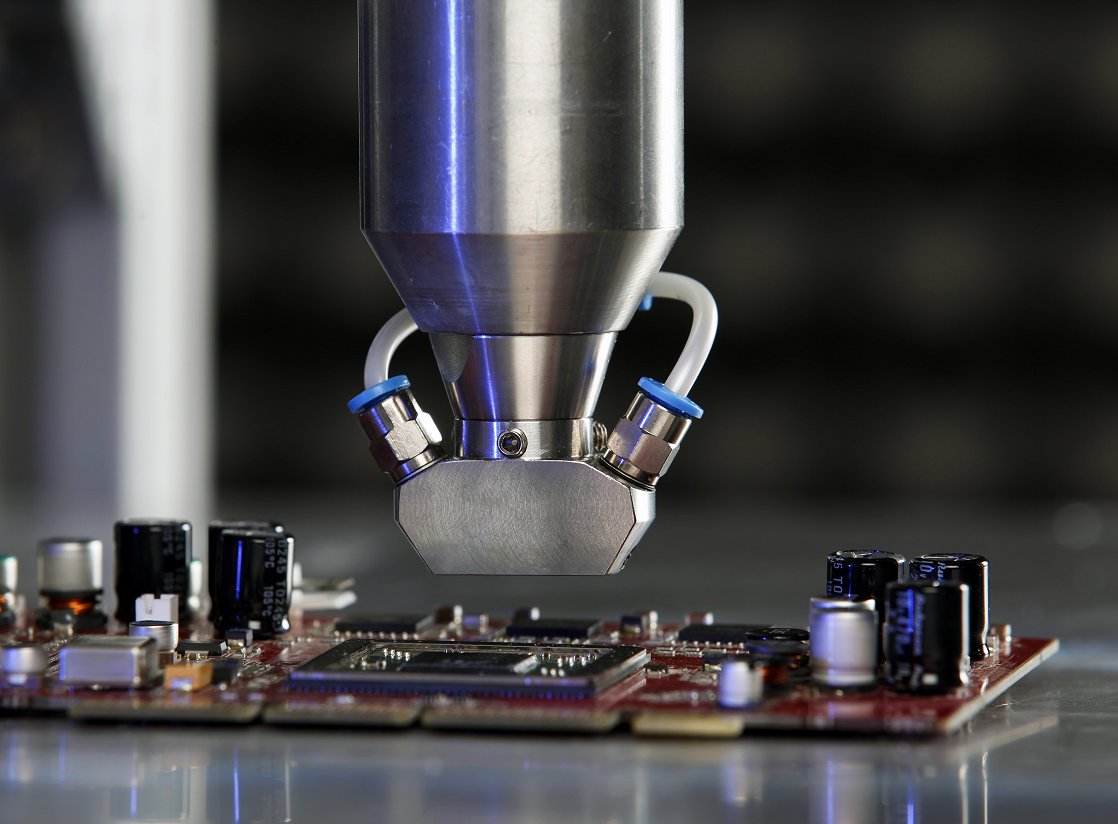

Plastic and paper based materials are used in a wide range of daily life products. Applications represent well established multi-billion Euro markets (e. g. food and pharma packaging, furniture surfaces, membrane-based filter systems, medical products etc.). New business opportunities will arise from replacing glass and metal by nano-functionalized plastic or paper surfaces in many products. That allows the reduction in weight and cost and gains in mechanical flexibility together with additional properties. Such properties include e. g. the blocking of water and oxygen permeation, surface conductivity, antimicrobial and anti-viral properties or chemical and corrosion resistance. State-of-the-art solutions often rely on composite or multi-layer materials. Such composites, however, have a major drawback with respect to their environmental footprint: they are neither fully recyclable nor compostable/degradable. Further, most plastic products are synthesized from mineral oil instead of renewable resources.

more information