The work of Fraunhofer Nanotechnology FNT covers the entire value chain from application-oriented research to assistance with industrial implementation. Here, for example, multifunctional coatings are developed for optical applications, automotive engineering and electronics. Metallic and oxide nanoparticles, carbon nanotubes/platelets and nanocomposites are used as structural and functional materials and also in biomedical applications. In addition, we address issues of toxicity, safe handling of nanomaterials and provide advice to potential users.

Business orientation is the guiding principle of the actions of the Fraunhofer Institutes in this topic-oriented network; this is reflected in project-related collaborations with industry as well as in public projects and the founding of new companies. Many of the Fraunhofer Institutes are actively involved in national and European nanotechnology networks.

About us

Competences of involved institutes

Nanomaterials

Fraunhofer Institute for Applied Polymer Research IAP in Golm

Nanotechnology approaches are widely used in the IAP to enhance and expand the performance, resource efficiency and application spectrum of both synthetic and biopolymer materials. Intrinsically nanostructured polymers, blends, and nanocomposites are new classes of materials in the plastics sector that not only make great advances in material adaptation and optimization, but also generate new properties. Polymeric nano-materials lead to highly reinforced or halogen-free flame-retardant components and fabrics, form the basis for adaptive and shape memory materials or essential components in display technology, sensor technology or optical measuring technology.

Polymeric nanoparticles and microparticles of uniform shape and size provide access to highly ordered pseudo-crystalline materials as well as tailored surface structures and properties. Nanoporous polymers are the basis for both electrical and thermal insulators and separation membranes and hollow fibers with optimized mass transfer or transport; they also allow the effective separation of nanoparticles.

Biological materials - such as tissue, blood cells or cell walls - provide numerous models for polymeric nanosystems and their use in the life sciences. Designed according to biological construction principles, polymeric nanomaterials are suitable, e.g. as mini reactors, for diagnostics, sensor layers or means of transport for (medical) active substances. Nanoscale polymer coatings and nanostructured surfaces can also be used to adjust and control interactions with biological material and organisms.

Since January 2018, the working group of the Center for Applied Nanotechnology CAN in Hamburg has strengthened the competences of the IAP, in particular in the field of synthesis, surface modification and analysis of nanoscale inorganic particles for applications in optoelectronics, electrocatalysis, life sciences and cosmetics.

Contact: Prof. Dr. Andre Laschewsky

Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden

As one of the leading research institutes for high-performance ceramics, Fraunhofer IKTS has set itself the goal to utilize the extraordinary properties of nanoscale materials in various fields of application, such as microelectronics, energy and environmental technology, mechanical and plant engineering as well as medical technology. Based on an exceptional range of processed inorganic, non-metal materials, a broad portfolio of state-of-the-art technical infrastructure as well as an extensive understanding of selected fields of application, Fraunhofer IKTS offers access to unique nanotechnology competences.

Nanoscale materials are used in the following selected fields of technology:

- High-performance ceramics for wear-resistant components with extreme thermal and chemical stability

- Membrane technology for environmental and process engineering

- Surface modification for scratch-resistant, non-stick, anti-corrosion, diffusion barrier layers

- Biofunctionalization of surfaces

- Nanoscale inks for microelectronics and power engineering

- Labeling solutions for workpieces and packaging in industrial process environments

- Biomolecular and cell-biological sensors

This is based on not only a comprehensive knowledge of the material potentials, the processing of nanomaterials and suitable application technologies, but also on a profound understanding of the material properties and interactions with other materials as well as with biomolecules and cells.

- Nanomechanical and structural characterization

- 3-dimensional distribution in the material

- Process and damage analysis

- Profound risk assessment

Contact: Dr. Annegret Potthoff and Dr. Jörg Opitz

Fraunhofer Institute for Silicate Research ISC in Wuerzburg

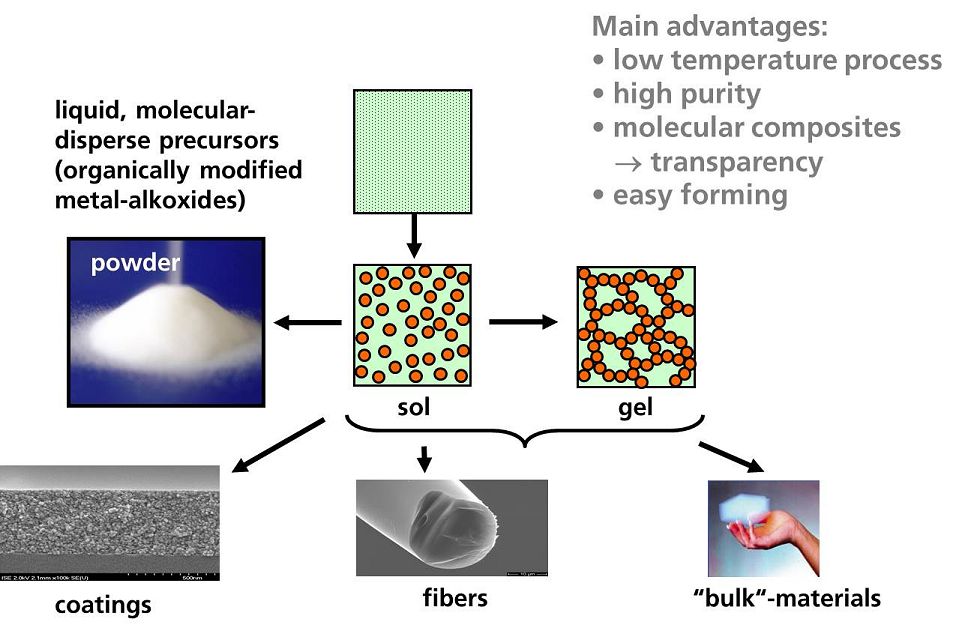

The focus of Fraunhofer ISC is on the synthesis of nanomaterials via solution-based chemical nanotechnology (sol-gel method) see figure left.

This technique is used for the production of inorganic nanostructures and inorganic-organic hybrid polymers ORMOCER®s. Beside hybrid polymers, particle technologies are another major focus at ISC (https://www.partikel.fraunhofer.de/en.html).

Particle technology

Offered are support for processing and upscaling of particles and particle based materials (composites and coatings) up to technical scale / pilot level. One highlight is the semi-continuous centrifugation equipment for nanoparticle separation. ISC also works on the combination of functional nano-units to complex multifunctional particles, called supraparticles, which can achieve new properties e.g. by incorporating optical and magnetic functions in suprastructures. Furthermore, additives can be synthesized which can be easily dispersed in polymer matrices due to programmable particle functionalization. Particle developments at ISC find appliction in waste water treatment, as filler in polymers, in battery materials and in biomedicine.

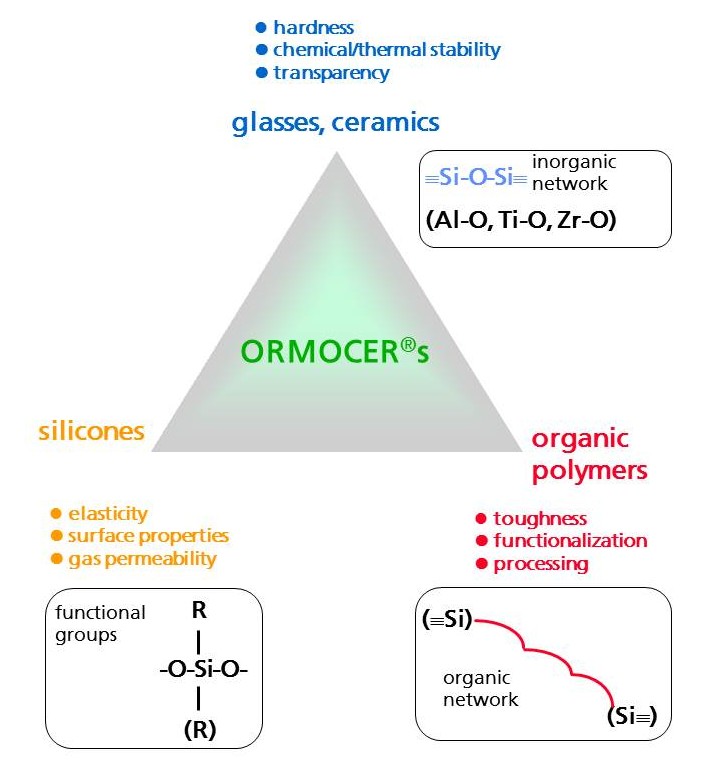

ORMOCER®s as nanoscale hybrid materials

ORMOCER®s are hybrid polymer materials that are synthesized by the sol-gel process combining inorganic and organic structural units on nano- and molecular scale. Initially, a nanoscale inorganic network is built by controlled hydrolysis and condensation of organically modified Si alkoxides. A co-condensation with other metal alkoxides (Ti, Zr, Al alkoxides) is also possible.

In a subsequent step, the polymerizable groups, as part on the inorganic network, are crosslinked by means of thermal or UV curing. In addition, organically modified Si alkoxides can be used, which do not undergo organic polymerization reactions and thus contribute to an organic functionalization of the inorganic network. Applications of these hybrid materials are widespread, from surface refinement to optical, electronic, biomedical and dental applications, see also www.isc.fraunhofer.de/en/fields-of-activity/materials/ormocer.html .

Contact: Dr. Carsten Gellermann

Fraunhofer Institute for Process Engineering and Packaging IVV in Freising

The Fraunhofer IVV researches and develops processes and products in the fields of packaging and food.

The focus is on packaging materials based on polymers for food and pharmaceutical products as well as technical applications. Mainly flexible plastic films with barrier properties or additional functions are developed and analyzed. To optimize the property profiles, nanomaterials are incorporated in the polymer film or in paint and adhesive systems. Competencies include film manufacturing and finishing as well as testing of material properties such as permeation and mechanical characteristics.

The emphasis in the area of food lies in the development of healthy food and convenience products. These may, for example, be high in fiber, high in protein or sugar reduced. Important research contents are:

- Development of food and functional ingredients

- Optimization of food quality and shelf life

- Process and product development for the use of vegetable raw materials

- Modeling approaches for predicting food shelf life and packaging optimization

Contact: Dr. Cornelia Stramm

Fraunhofer Institute for Material and Beam Technology IWS in Dresden

The production and application of nanoscale structures play an increasingly important role in innovative products and are also of key importance for Fraunhofer IWS. Examples include the production and optimization of nanostructured ultra-hard ta-C coatings, which, due to their very high wear resistance and extremely low friction, have a very broad application potential in many industries. Furthermore, the IWS has extensive expertise in the production of high-precision nanometer multilayers, such as those used in nano-lithography or X-ray optics. Nanoscale reactive multilayers allow a precise and gentle so-called "cold" joining of a wide variety of temperature-sensitive materials.

In addition, the IWS is involved in the development and production of nanocomposite electrodes for lithium-sulfur batteries based on vertically oriented carbon nanotubes or nanoporous carbons.

The IWS is also active in the development of new metrological methods and components. For example, the IWS is developing new high-resolution X-ray lenses that allow non-destructive testing with a resolution of just 25 nanometers. With a specially developed laser-acoustic process, coating properties down to the nanometer range can be characterized nondestructively.

Contact: Prof. Dr. Andreas Leson

Nanobiotechnology

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in Stuttgart

The Fraunhofer IGB develops and optimizes processes, products and technologies for the health, chemical and process industries as well as the environment and energy sectors. The institute offers complete solutions from market analysis to research and application-ready development. Customers also benefit from the constructive interaction of the various disciplines at the institute, which opens up new approaches in areas such as medical technology, nanobiotechnology or industrial biotechnology.

The research activities of the Fraunhofer IGB in the field of nanotechnology are characterized by the manifold competencies of the institute in the field of materials as well as life sciences. They include the design, synthesis, (bio-) functionalization and work-up as well as the characterization and risk assessment of nanomaterials such as nanoparticles, carbon nanotubes, nanofibrillar cellulose and nano- and microstructured layers. The latter are being developed, for example for anti-ice equipment or as barrier layers.

Technologies

- Nanoanalytics: surface analysis, nanoparticle characterization

- Nanostructuring, nanocoating: Functional layers, encapsulation, release and transport of active substances and effect substances

- Nanomaterials: polymers and polymer composites, inorganic-organic hybrid materials, biomaterials

Application fields

- Diagnostics, drug development, medical technology, cosmetics

- Coating / finishing of materials, packaging, textiles

- Analytics, biosensors, detection systems

- Pollutant removal, membrane separation systems

Contact: Prof. Dr. Günter Tovar

Fraunhofer Institute for Molecular Biology and Applied Ecology IME in Aachen

Fraunhofer IME is dedicated to research from the molecule to the ecosystem. A major focus here is the development and application of cutting-edge technologies for improved diagnosis and treatment of diseases in humans and animals and for the protection of food, feed and agricultural products. To achieve these goals, nanobiotechnology is also becoming increasingly important. The development and establishment of new innovative analytical methods and detection technologies is one research focus at the IME in Aachen. For example, magnetic nanoprobes are used to develop new and efficient detection strategies. Magnetic nanoparticles functionalized with biomolecules can be used for magnetic labeling, separation and enrichment of a wide variety of analytes. The magnetic markers can then be quantitatively detected using a magnetic detection method to infer the amount of analyte to be detected. Due to its ease of use and rapidity, the magnetic immunodetection method is particularly suitable for rapid test applications. In recent years, rapid tests have been developed on this basis for the detection of pathogens and toxins in food, agricultural products and drinking water, for the diagnosis of plant diseases or also with regard to medical diagnostic issues, for example in connection with the Corona pandemic.

In addition, IME is engaged in research on "quantum biosensors" in collaboration with Fraunhofer ISC to develop the next generation of lab-on-a-chip-based "point-of-need" technologies for biomedical and industrial applications. These novel sensors utilize biohybrid nanomaterials called DNA-stabilized metal quantum clusters (QC-DNA). These consist of short single-stranded DNA oligonucleotides and metal atoms, whose binding forms a fluorescent biohybrid nanocluster. The choice of DNA sequence determines the fluorescence of the sensor and determines which analyte or pathogen is detected. Interaction effects between the QC DNA and the analyte cause a specific and highly sensitive change in the fluorescence properties of the QC DNA, which enables simple, fast and accurate detection.

Contact: Dr. rer. nat. Florian Schröper

Fraunhofer Institute for Toxicology and Experimental Medicine ITEM in Hannover

For more than 30 years, Fraunhofer ITEM has been engaged in toxicological research, with a focus on the toxic mechanisms and effects of inhaled substances in the respiratory tract. The institute performs contract research on behalf of the pharmaceutical and chemical industries as well as for the public sector. In the past decade, pharmaceutical research competencies in particular have been continuously expanded. Besides molecular (omics methods), preclinical and clinical pharmaceutical research (focus on allergy and asthma research), which have meanwhile become established, toxicological investigations on occupational and environmental issues and in the field of consumer protection play a pivotal role. The institute’s scientists have long-standing expertise in the characterization and toxicological investigation of particle and fiber aerosols. For man-made mineral fibers, Fraunhofer ITEM has developed a standard test for in-vivo biopersistence analysis.

The intense current debate about the toxicological assessment of engineered nanoparticles has resulted in "nanotoxicology" becoming another research focus at Fraunhofer ITEM. The Fraunhofer Nanotechnology Alliance aims to establish a battery of in-vitro assays that will allow producers to characterize the toxicological potential of newly developed nanoparticles rapidly and at affordable costs before launching these on the market.

Contact: Dr. Gustav Bruer

Nanooptics / Nanoelectronics

Fraunhofer Institute for Integrated Systems and Device Technology IISB in Erlangen

Fraunhofer IISB conducts applied research and development for complex electronic systems for use in electromobility, aerospace, Industry 4.0 or energy and network technology. The institute covers the entire value chain from basic materials to microelectronics, nanoelectronics and power electronics technologies as well as complete power electronic systems.

With its two business units, Semiconductor and Power Electronics, the Institute develops innovative solutions in the following areas:

- Materials

- Semiconductor Process Technology

- Nanostructuring

- Electronic Components

- Construction and connection technology

- Vehicle electronics systems

- Systems for power engineering and electrical energy supply

This is complemented by broad cross-sectional activities in the area of simulation, measurement technology as well as lifetime and reliability investigations.

Contact: Dr. Jürgen Lorenz

Processes, Analytics, Consulting

Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart

At Fraunhofer IPA, in the field of surface technology, projects from the entire area of the coating technology process chain are tackled. Improved efficiencies, shorter throughput times, energy and material savings are sought-after solutions, which, after support during implementation and integration, significantly increase process efficiency, whereby solutions with nanoscale components play an important role.

Surfaces gain new properties by incorporating functional components into their coating. The spectrum ranges from electroconductive coatings, electrical resistance heaters, printed large-area sensors to technologies for a real human-machine interface using printed actuators. To achieve these results, conventional materials are modified with functional fillers. These smart materials are custom synthesized, functionalized, dispersed and applied. In the modular expandable model factory, scale-up examinations are possible, allowing product ideas and production processes to be quickly and adequately tested for feasibility. The digitalization of these processes creates the basis for the introduction of numerical solutions and new business models.

Relevant priorities in detail:

- Electrode production in the technical center "Flexible Battery Production"

- Dispersing technique

- Application of multifunctional layers

- Surface inspection by means of non-contact methods

- Coating system and painting technology

Contact: Dipl.-Ing. FH Ivica Kolaric MBA

Fraunhofer Institute for Systems and Innovation Research ISI in Karlsruhe

Fraunhofer ISI analyzes the origins and effects of innovations. We explore the short- and long-term developments of innovation processes and the social impact of new technologies and services. On this basis, we provide our clients from business, politics and science with recommendations for action and perspectives for important decisions. Our expertise lies in founded scientific expertise and an interdisciplinary and systemic research approach.

Fraunhofer ISI has many years of experience in the field of nanotechnologies. For example, we are leading the industrialization work package in the Graphene Flagship Project of the European Union, where we are responsible for a comprehensive technology and innovation roadmapping process.

Contact: Dr. Henning Döscher